Highlights

- Corner Cleaning of PVC Frames

- High-Speed, Maximum-Quality Operation

|

Description

|

|||||||

| Machine Features | Max. Profile Size | mm | 220 | 130 x 220 | |||

| Min. Profile Size | mm | 130 | __ x 20 | ||||

| Max. Frame Size | mm | 340 x 340 | - | ||||

| Min. Frame Size | mm | 0,75 | 340 x 340 | ||||

| Motor Speed | cycle/min | 0,4 | 12000 | ||||

| Diameter | mm | 0,75 | 250 | ||||

| Saw | Motor power | 1,5 | kW | ||||

| Saw | Rotation Speed | 12000 | rpm | ||||

| Saw | Diameter | 250 | mm | ||||

| Machine Dimensions | Pressure | bar | 6-8 | 6~8 | |||

| Total Air Consumption | Lt/min | 45 | 90 | ||||

| Voltage | V | 230 | 220/230 | ||||

| Power | kW | 4,5 | 4,0/4,0 | ||||

| Net Machine Weight | kg | 935 | 935 | ||||

| Gross Weight | kg | 1060 | 1060 | ||||

| Sound | d(b) | 96 | 96 | ||||

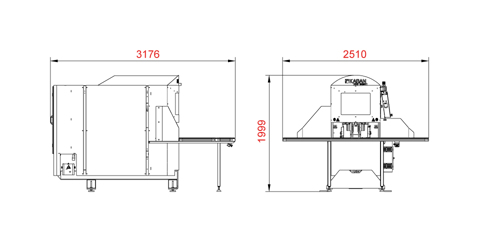

| Length(L) | mm | 2510 | 2500 | ||||

| Width(W) | mm | 3176 | 3150 | ||||

| Height(H) | mm | 1999 | 2000 | ||||

Design

- Robust mechanical design allows you to process PVC profiles with

maximum quality for many years, at high speed.

- It is designed to clean PVC frame corners made of 90o angle.

- Cleaning of a corner in min. 9 sec.- max.18 sec. according to profile type.

- It is designed to clean PVC frame corners made of 90o angle.

- Cleaning of a corner in min. 9 sec.- max.18 sec. according to profile type.

Control Panel

- Mitsubishi PLC, control equipment and easy-to-use portable LCD

display

- Software which allows to create receipts at laminated-unlaminated, with gasket-without gasket categories.

- Practical and user friendly parameter settings.

- Automatic profile defination feature thanks to measuring and control systems

- Software which allows to create receipts at laminated-unlaminated, with gasket-without gasket categories.

- Practical and user friendly parameter settings.

- Automatic profile defination feature thanks to measuring and control systems

Stripping Blade

- Scraping blades clean the burrs on the lower and upper surfaces

of the profile caused by the welding process.